Which Process Produces Ceramic Particles With Most Uniformity

The next step is to form the ceramic particles into a desired shape.

Which process produces ceramic particles with most uniformity. 1 according to the preston equation the physical model mrr kpv keεωr has been established in our previous work where e is the young s modulus ε is the strain ω represents the rotational angular velocity of the fg cs lpp and r represents the distance of the contact point from the rotation center. 5735976 ceramic particles formed in situ in metal. Fine micron sized sic powders and coarse micron sized. Ceramic nanoparticle is a type of nanoparticle that is composed of ceramics which are generally classified as inorganic heat resistant nonmetallic solids that can be made of both metallic and nonmetallic compounds.

Hybrid ceramic particulate reinforced a356 aluminium composites were prepared via the semi solid stir casting process followed by hot rolling. The stöber process is a chemical process used to prepare silica sio2 particles of controllable and uniform size for applications in materials science it was pioneering when it was reported by werner stöber and his team in 1968 and remains today the most widely used wet chemistry synthetic approach to silica nanoparticles. 75 368 5405427 salt flux for addition to molten metal adapted for removing constituents therefrom and methods of using 1995 04 11 eckert 75 308 5401338. Us5098740a us07 450 200 us45020089a us5098740a us 5098740 a us5098740 a us 5098740a us 45020089 a us45020089 a us 45020089a us 5098740 a us5098740 a us 5098740a authority us unite.

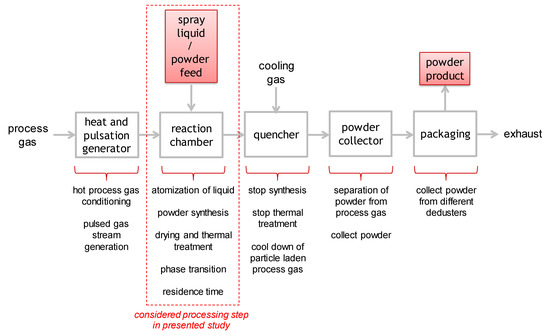

Source classification codes in parentheses 7 96 mineral products 11 7 3 0 017 to 0 0015 in 40 to 400 mesh. 1998 04 07 chu et al. This is done either by. Process flow diagram for ceramic products manufacturing.

Ceramic powders prepared in this way. Some of the most common. Simulation of the outside of the space shuttle as it heats up to over 1 500 c 2 730 f during re entry into the earth s atmosphere bearing components made from 100 silicon nitride si3n4 ceramic bread knife ceramic engineering is the science and technology of creating objects from inorganic non metallic materials. Thus ceramic nitride or carbide particles are coated with densification aids such as yttria by the surface precipitation of the corresponding hydroxides on the ceramic particles in water.