Thin Film Ceramic Substrates

Alumina is an optimal material for most thin film ceramic substrate applications.

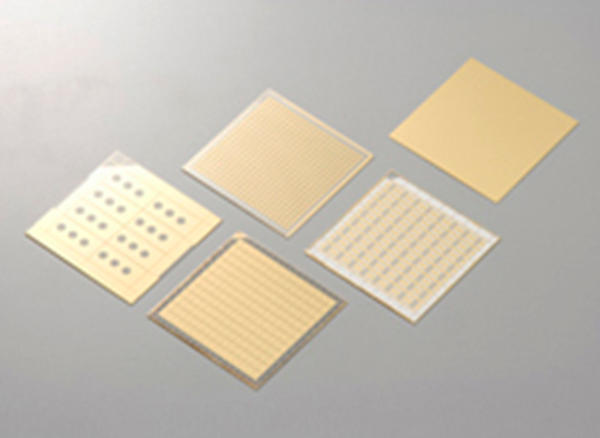

Thin film ceramic substrates. The circuits are mainly done for thin film substrates are coated by a pvd process. Ceramic substrate requirements. Multilayer circuits on ceramic with polyimide as the insulator material. Thick film substrates are electronic circuit boards generally made from ceramics.

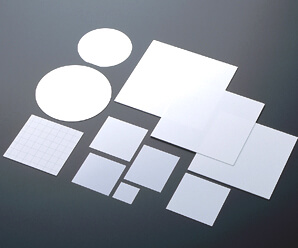

Thin film substrates thin film substrates with superior surface smoothness. Coorstek controls surface finish grain size and surface imperfections to enhance fine line resolution spacing and yields in your thin film process. Thin film substrates on polymer ceramic steel glass ferrite etc. Therefore high demands with respect to the surface and grainsstructure of the ceramic substrate are made.

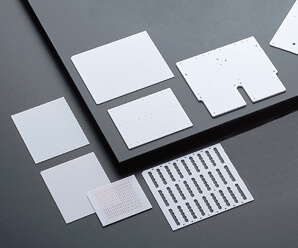

Our precision etching technology pushes thick film ceramic substrates to a best in class position offering the tightest tolerances and the highest performances rivaling thin film capabilities. The ceramic powder for the particular sensor substrate material must therefore have a particle size of about 1 micron. Your one stop provider for ceramic packaging solutions. If it s possible in thin film chances are it can be realized in etched thick film at a fraction of the price.

Thin film ceramic substrates 99 6 alumina up to 300mm diameter and 12 square. Hybrid circuit ceramic substrates. The ceramic is screened with conductor insulator and resistor material to form the circuitry. Thin film substrates made of 99 6 alumina offer superior surface smoothness.

Tecdia s engineers push the limits of ceramic technology while maintaining the standard of quality that tecdia has always been known for. Thick copper thin film circuits for high performance applications. Ceramics and ceramic substrates for thin film and thick film microelectronic photonic and electro optic applications. Flexible multilayer circuits with very high resolution 10 µm 0 4 mil integrated resistors and couplers.

Remtec uses pctf and other advanced technologies to design and produce cost effective custom and semi custom packaging solutions metallized substrates packages and components for power electronics optoelectronics and rf mw applications in commercial industrial and military industries. Mpt is a one stop shop for your thick film substrate needs. Why ceramic thin film substrates. Using a wide array of ceramic substrate materials and metal systems combined with advanced thin film manufacturing features and capabilities the circuit designer can now easily reduce circuit size and parts count over traditional thin film substrate design approaches while also enhancing performance.