Thermal Properties Of Ceramic Wool

Othman1 b and f.

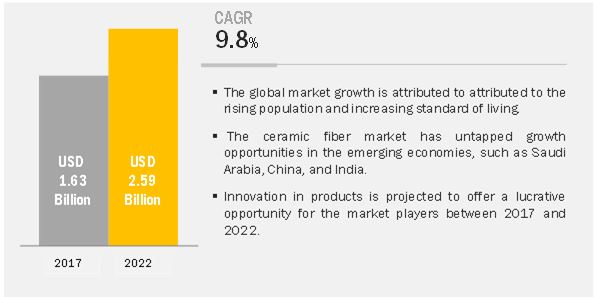

Thermal properties of ceramic wool. Fire resistance properties of ceramic wool fiber reinforced intumescent coatings n. Thermal ceramics offers high temperature fibre blankets for applications in thermal management and passive fire protection. Ahmad1 c 1mechanical engineering department universiti teknologi. Thermaxx proudly uses fiberfrax ceramic fiber insulating blanket and mats.

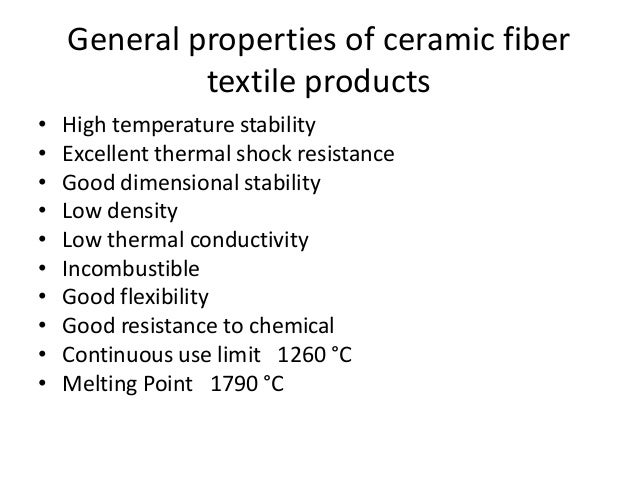

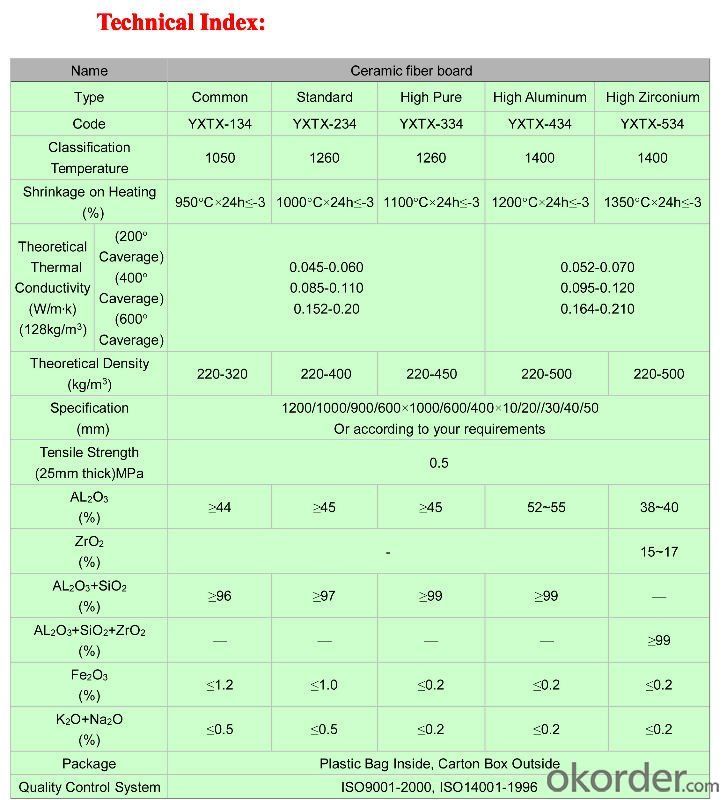

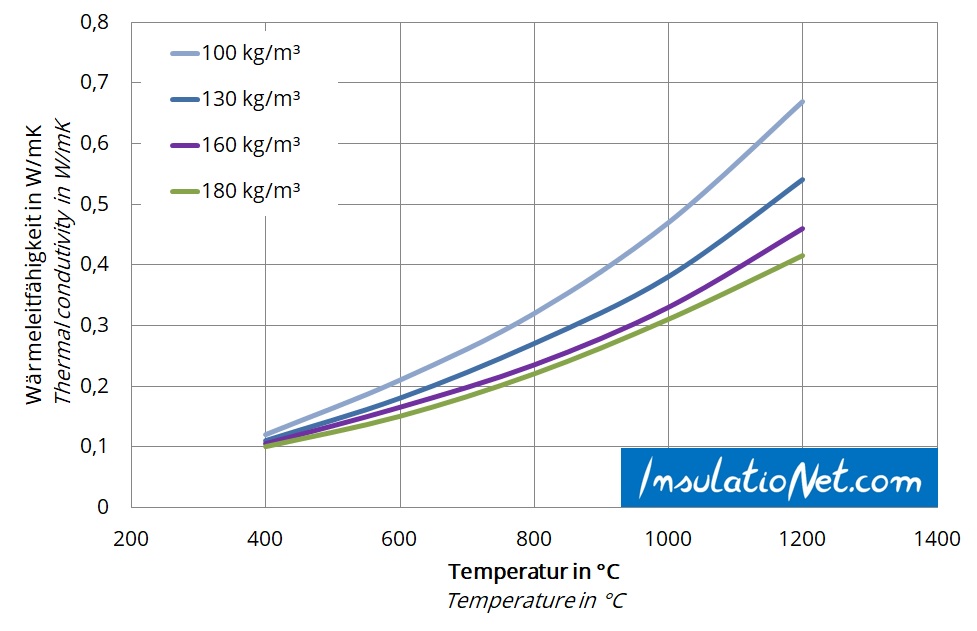

Aluminum silicate wool asw is based on the al2o3 sio2 system and is in use since more than 50 years. The results of influence of glass fiber addition into the basic intumescent coating formulation towards the enhancement of its thermal insulation properties are presented. Ceramic fiber materials are required for the thermal insulation of the hot gas zones of components carrying process gases. They can also be amorphous or have inhomogeneous chemical composition which develops upon pyrolysis of organic precursors the high process temperatures required for making cmcs preclude the use of organic metallic or glass fibers only fibers stable at temperatures above 1 000 c 1 800 f can be used.

Low biopersistent fibres are provided as superwool blankets with. The exceptional thermal fire and acoustic properties of mineral wool derive from the mat of fibres that prevents the movement of air and from mineral wool s inert chemical composition. Bühl in concise encyclopedia of advanced ceramic materials 1991. These must be corrosion and erosion resistant and must also be free from shrinkage at temperatures up to 1400 c.

It is a very versatile material and can be manufactured to many different densities to give varying properties formed in various shapes and faced with a. Undoubtedly ceramic wool felt with low moisture absorption light weight low thermal conductivity and non combustible property is expected to provide a new solution in the fields of industrial. The high temperature wool also referred to as ceramic fiber or refractory ceramic fiber rcf has fundamentally changed plant engineering and furnace construction due to its properties. The intumescent coatings were formulated from expandable graphite ammonium polyphosphate melamine boric acid bisphenol a epoxy resin be 188 polyamide amine h 2310.

.jpg)