The Ultimate Tensile Strength Of Metal And Ceramic Matrix Composites

Tensile and flexural ultimate strength of fiber reinforced ceramic matrix composites author links open overlay panel françois hild jean marc domergue frederick a.

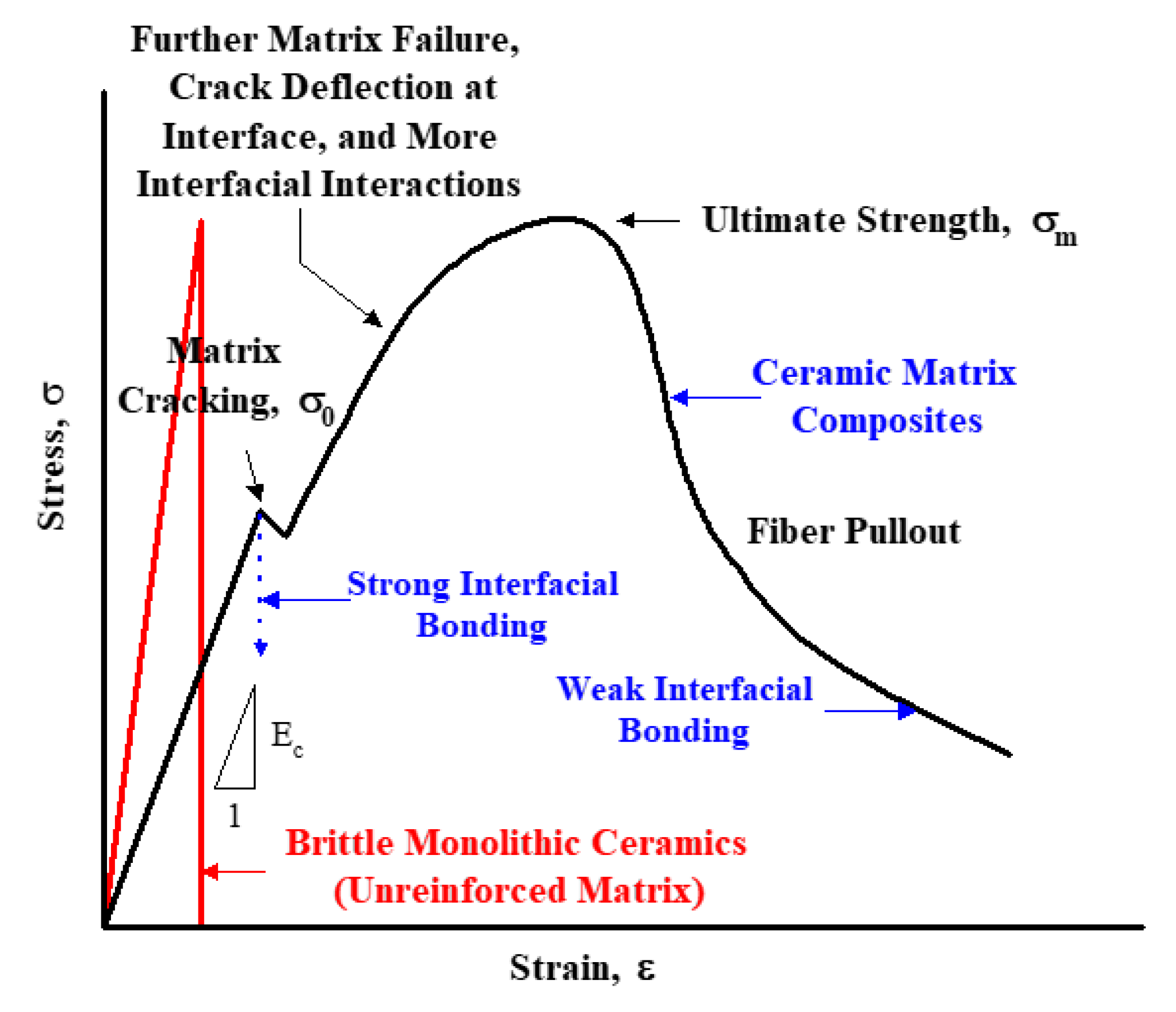

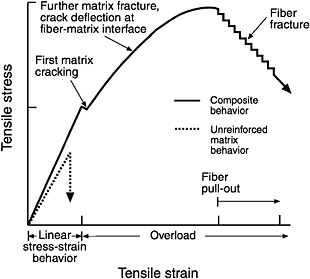

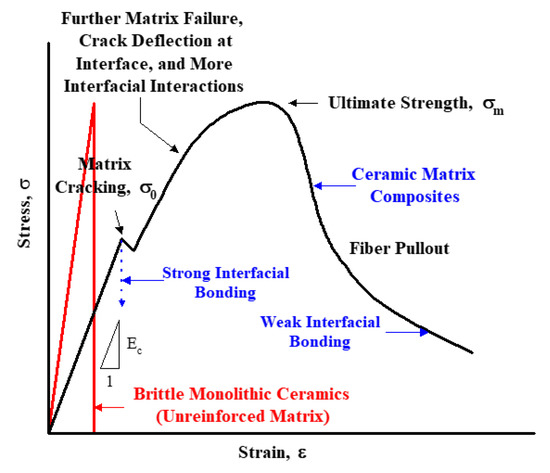

The ultimate tensile strength of metal and ceramic matrix composites. The mechanical properties of this interface dictate the stress concentration that develops in fibers that surround a. The tensile strength of ceramic and metal matrix composites is subject to an important role of the fiber matrix interface. They consist of ceramic fibers embedded in a ceramic matrix. Leckie anthony g.

The mechanical properties of this interface dictate the stress concentration that develops in fibers that surround a failed fiber. Tensile and fracture tests were conducted at 20 and 1200 c on a ceramic matrix composite that was composed of an alumina al 2o 3 matrix that was bidirectionally reinforced with 37 vol silicon. Both the matrix and the fibers can consist of any ceramic material whereby carbon and carbon fibers can also be considered a ceramic material. However there are conflicting reports on the tensile strengths attainable.

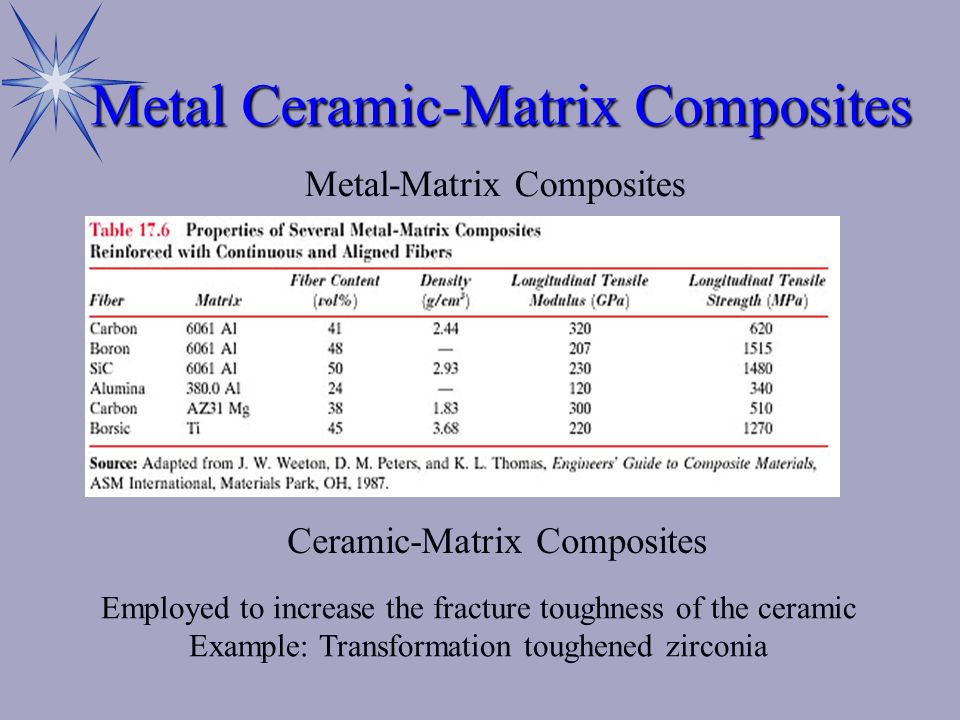

There is intensive interest in metal matrix composites mmcs for automotive components and the first production applications in japan use discontinuous fibers as the reinforcements. These fibers are randomly oriented resulting in an mmc with isotropic properties. The mechanical properties of this interface dictate the stress concentration that develops in fibers. Response to a comment on the ultimate tensile strength of metal and ceramic matrix composites author links open overlay panel a g evans w a curtin show more.

The tensile strength of ceramic and metal matrix composites is subject to an important role of the fiber matrix interface. In some cases the strength increases with increasing. The investigated ceramic matrix mini composites were manufactured using a nextel 610 fibre roving with a linear mass density of 3000 den which corresponds to a nominal filament count of 750 and an aqueous ceramic slurry of α al 2 o 3 particles with an average particle size of approximately 200 nm prepared from pural boehmite powder. An analysis of this phenomenon is used to illustrate interface conditions that sufficiently diminish the stress concentration that a global.